AzuLoop

- Berta Marco

- Luna Hongenaert

- Esmée Keijzer

- Kristoffer Julin

- Akseli Järvimäki

- Darius-Alexandru Ion

Acknowledgements

Abstract

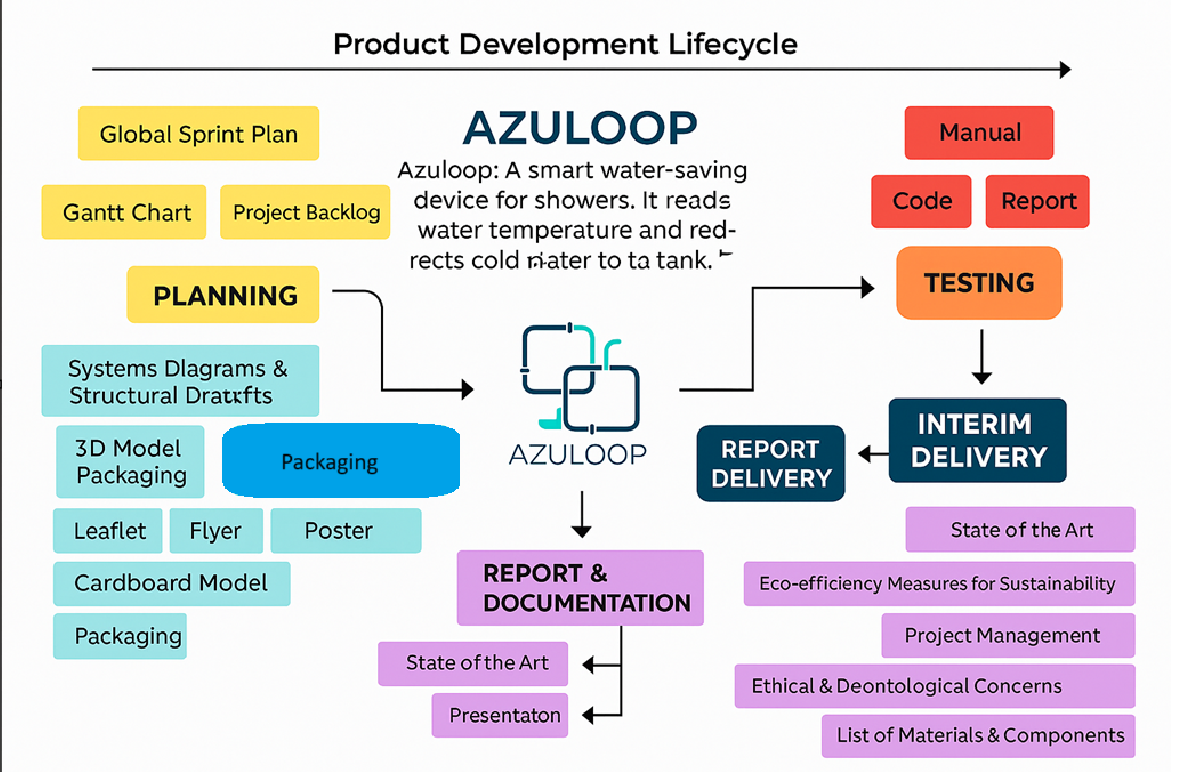

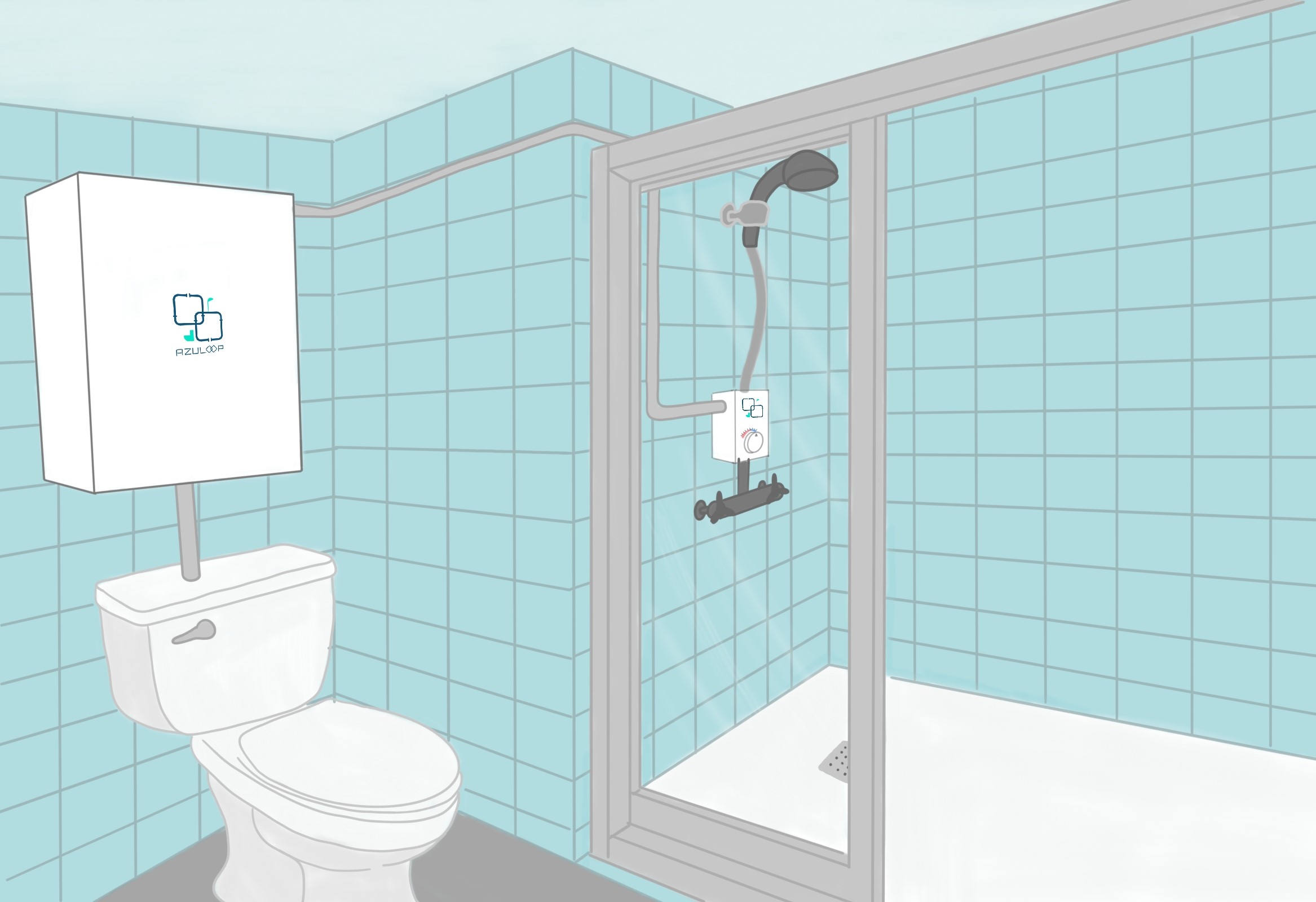

The European Project Semester (EPS) is an innovative engineering capstone project semester. Currently, the programme is offered by 20 European universities, including the Instituto Superior de Engenharia do Porto (ISEP). EPS employs a learning framework based on real-world challenges, interdisciplinary projects, and multicultural and multidisciplinary teamwork. Teams are required to design solutions based on market and state-of-the-art analyses, adhere to ethical and sustainability principles, and develop and test a proof-of-concept prototype. In the spring of 2025, an EPS@ISEP team decided to address the issue of domestic water waste. The most apparent waste occurs when users turn on the tap and wait for the water to heat up, sending clean water down the drain. The designed solution eliminates this waste by redirecting water below the temperature set by the user from the shower to an additional toilet water tank. AzuLoop consists of a smart shower mixer, a water tank that adapts to existing toilet water tanks, and a few additional pipes. AzuLoop is easy to install, provides a comfortable shower experience, and reuses the clean cold shower water. During the semester, the team successfully designed, developed, and tested the AzuLoop prototype, while gaining valuable technical and personal skills through collaborative learning

Glossary

| Abbreviation | Description |

|---|---|

| EPS | European Project Semester |

| ISEP | Instituto Superior de Engenharia do Porto |

| USB | Universal Serial Bus |

| WBS | Work Breakdown Structure |

1. Introduction

1.1 Presentation

This project was completed by a team of six students, each with a different academic background. They are presented in Table 1.

| Akseli Järvimäki | Finland | Civil Engineering |

| Berta Marcó Gimenéz | Spain | Mechanical Engineering |

| Darius-Alexandru Ion | Romania | Industrial Informatics Engineering |

| Esmée Keijzer | The Netherlands | Communication and Media Design |

| Kristoffer Julin | Finland | Electrical Power Engineering |

| Luna Hongenaert | Belgium | Product Development |

1.2 Motivation

We all came to ISEP with the ambition to create an innovative and impactful project. By combining our knowledge and skills, we aimed to achieve an optimal result that is not only technically strong but also provides real value. The EPS programme is supported with other courses about topics that enhance our project and make us consider different perspectives of it.

Individual motivation

- Luna - I chose the EPS programme because I often love to work in a team with students from different backgrounds because I know all the better that working in the real-world, this would be the standard. Also the hands-on approach is interesting because we learn mostly from each other and the proces of the project rather than on dry class material. I'm looking forward to step out of my comfort zone and take projects that are not in my expertise to learn new skills and face new challenges.

- Berta - My motivation to choose EPS program was broadening my horizons by working together with people from other cultures and learning from each other. Also I wanted to challenge myself by living on my own in a whole new country and having fun from people from all around Europe.

- Esmée - I chose the European Project Semester, because I am excited to work with people from different educational and cultural backgrounds. I want to experience living on my own in a foreign country, it will be a challenge to solve problems in my personal time and in the EPS project. I have to work outside of my comfort zone , because engineering has nothing to do with my main studies. This is a unique opportunity to come up with creative solutions to implement User Experience Research & Design and it is also an opportunity to learn more outside of my usual field of work.

- Darius - As an Industrial Engineering and Computer Science student, being part of the European Project Semester (EPS) in Porto at ISEP allows me to apply my technical expertise in an interdisciplinary, real-world setting. My experience with AI-based image recognition, additive manufacturing, and sustainability projects has strengthened my problem-solving, teamwork, and innovation skills. Through this program, I am enhancing my engineering knowledge, collaborating in a diverse environment, and developing sustainable solutions that align with my passion for electric propulsion and mobility technologies. EPS is a perfect opportunity to bridge my academic background with practical industry challenges while growing as an engineer and global team player.

- Kristoffer - I chose the EPS program because it seemed like a convenient way, to combine courses with a project, and then apply the knowledge from the courses to the actual project. Another reason why is to learn how to work in a multicultural environment, and learn how to work in a multidisciplinary field.

- Akseli - I chose the EPS program because it offers a structured way to merge theoretical learning with practical project work. It also provides a great opportunity to apply course knowledge to real-world challenges. Another key reason was the chance to gain experience in a multicultural and multidisciplinary work environment.

Project motivation

Beyond our personal motivation to participate in the EPS project at ISEP, we are strongly driven by our chosen topic. Smartifying everyday objects can be very diverse, but we see it as an opportunity to use our technical skills and knowledge on a topic that inspires us and that is challenging enough to work on an entire semester on it. We want to deliver a project we can be really proud of.

We started with identifying the design focus, namely sustainability. This way we are able to contribute to environmental improvements in our own way and set a clear goal for this project. Water consumption in everyday households stood out for us as an issue that we are able to understand, extremely relevant all over the world and it is tangible enough to contribute to a solution. Water usage is something we deal with daily on both environmental and financial terms. We hope with just a few adjustments in the daily household, we can contribute to reducing unnecessary water waste with just a small addition or transformation to an already existing object.

By tackling this problem we are not only creating a solution, but we are also raising awareness and encouraging others to consume water in a responsible way. This challenge offers an opportunity for us to gather our technical skills and knowledge to create something meaningful and make a real difference in the way we interact with essential resources.

1.3 Problem

Water waste is a widespread issue. A study by Water Practice and Technology estimates that approximately 20 % to 50 % of all usable water is lost due to leaks, poor infrastructure, or inefficiency. Household water waste ranks as the second largest contributor to this problem, following agriculture. One significant yet often overlooked source of household water waste is the water lost while waiting for the shower to reach the desired temperature [Bassey James, 2025].

This type of waste, known as warm-up waste, varies depending on the household's plumbing system and the distance between the water heater and the shower. In cases where the heater is not located near the shower, it can take up to 60 seconds for hot water to arrive. If one assumes an average wait time of one minute, approximately 5.6 liters of clean water is wasted per shower. In a household of four people showering daily, this amounts to 24.4 liters per day or 8.906 liters per year [Evolve Technologies, 2025].

Beyond water waste, this also translates into financial loss. In Portugal, the cost of water is 0.001 7 € per liter, meaning that a family of four could save around 15.14 € per year by simply redirecting and reusing this cold water instead of letting it go to waste [TPN, 2024].

Reducing warm-up waste is not only beneficial for household expenses but also has a significant environmental impact. Although 71 % of the Earth's surface is covered in water, only 3 % is freshwater, and just 0.5 % is accessible for human use. The less water people waste, the smaller the strain on water resources and wastewater systems. Additionally, minimizing wastewater discharge helps reduce the introduction of harmful chemicals into natural bodies of water such as rivers, lakes, and oceans, protecting aquatic ecosystems and biodiversity [4].

1.4 Objectives

Our goal is to develop a simple yet effective system that significantly reduces household water waste, potentially decreasing shower water consumption by up to 10 %. Instead of letting cold water run down the drain while waiting for the shower to heat up, our system will redirect it to an extra tank above the toilet, allowing it to be reused for flushing.

The product is a separate device that is installed between the water mixer and the showerhead. It includes a temperature sensor, a microcontroller, and two solenoid valves: one that directs water to the showerhead when the desired temperature is reached and another that redirects cold water to the toilet tank when it is not warm enough yet. The extra tank above the toilet has a float sensor that measures the water level to make sure if the stored water can or should be used to flush the toilet.

By applying this product, the team wants to minimize water waste while the user doesn't has to change their daily behaviour or make too much effort. The process is completely automated, which makes water management and sustainable behaviour effortless.

1.5 Requirements

Specify here the identified and mandatory requirements the solution has to fulfil

User interaction:

- Safe to use around water.

- Easy to use, intuitive.

- Possibility to personalize user settings.

- Make the user aware of their actions.

Interior:

- Usable water saving system

- Energetic efficient

Exterior:

- Attractive design.

- As small as possible.

- In harmony with the surroundings

Others:

- Budget friendly

- Ecologic

1.6 Tests

The main objective of building a prototype is to test the product's functionality. Prototype functional testing is a crucial step to validate if the product can be brought into real life. To guarantee the best result and experience for the users, the team will conduct several tests on the prototype.

- Structural test:To verify the structural adequacy and integrity of the water tank under hydrostatic pressure loads, a comprehensive stress analysis will be performed using SOLIDWORKS Simulation. The tank will be subjected to 30L water capacity (equivalent to 1,720 Pa maximum pressure at the bottom) through nonuniform pressure distribution simulation. The analysis will evaluate von Mises stress concentrations, particularly at critical locations such as base-wall junctions and corner regions where maximum stresses occur. Material yield strength will be compared against calculated maximum stresses to ensure a minimum safety factor of 2.0. Displacement analysis will verify that wall deformations remain within acceptable limits. The structural test passes if maximum stress values stay below material yield strength with adequate safety margins, and if no excessive deformation or structural failure occurs under the specified hydrostatic load conditions.

- Software test: To make sure the components and their connections are well planned, the team will simulate the software test first with Tinkercad.Afterwards, the testing of all input values will be done, the water level switches, the temperature sensor, and the potentiometer. Making sure values are similar to reality. Mapping the potentiometer so it represents the temperature values correctly. Checking if the valves can be controlled through the relay through the microcontroller. Making sure the valves are activated at the right time based on said temperature , and the level of the tank.

- Electrical test: Test the electrical components of the system, and the automation (in this case the microcontrollers switching properties), relays, and solenoid valves. In this case the test will be done by applying both a 5 and a 12 voltage from the power supply to the electrical components, 5 V will be applied with jumper cables, and the solenoids will be tested by applying 12 V from the relays switches by using a cable with fast connector terminals. How the team determines whether the electrical test passes or not is based on the functionality of the relays and solenoids, If the solenoids and relays work (the relay pulls & the solenoid opens), the test passes, If not, the test automatically fails.

- Real quality prototype test: Testing the complete product's functionality as fully assembled, and in a normal working environment, in order to make sure that it complies with our quality standards. Here both the software and the electrical parts go through another test phase, simultaneously with the hardware test to make sure it withstands the affecting stress caused by water pressure, this test will be done by mounting the water hoses to a water mixer with a threaded connector, the team will gradually increase the water pressure to make sure it withstands the requirement. How the team determines whether the Real quality prototype test passes or not is based by the system's whole functionality ( Software & electrical test & stress test combined). The Real quality prototype test passes if the electrical test passes as announced on the electrical test part, and the Software test passes as announced on the Software test part. Also the pipes and their connectors should withstand 3 bar water pressure without any leakage from pipes or pipe fittings. If the prototype does not meet these requirements it does not pass the test and automatically fails.

With these tests, the team will conclude whether the product is viable or should be redesigned. The team's aim is to ensure a good product with good quality, in this case the test will be completed by installing our product to a water mixer, from where the team can regulate the warm/cold water distribution and therefore test the sensors and switching properties, as well as make sure our product withstands the affecting water pressure.

1.7 Report Structure

| Chapter | Description |

|---|---|

| 1 Introduction | Team and problem introduction |

| 2 Background and Related Work | Research and analysis on the current solutions for the chosen problem |

| 3 Project Management | Planning method and structure that will be followed by the team |

| 4 Marketing Plan | Marketing strategy developed by the team to launch the project successfully |

| 5 Eco-efficiency Measures for Sustainability | Sustainable and ecological concerns considered in the project |

| 6 Ethical and Deontological Concerns | Ethical and Deontological concerns considered in the project |

| 7 Project Development | Report of the progress and development of the solution |

| 8 Conclusions | Conclusions the team gets from the final solution |

| 9 Bibliography | List of information sources |

2. Background and Related Work

2.1 Introduction

In order to have an overview of the actual market and solutions to the problem, it is fundamental to do a state-of-the-art research.

Below there's research on different products that help solve the problem of water wasting, and some projects that help spread awareness of water being a finite good and solutions to the problem.

Finally, the comparative analysis helps define the current solutions' areas of action and identify their weaknesses and strengths.

2.2 Concepts

Some concepts that help understand the main problem and the proposed solution are:

- Water flow It's defined by the volume of water moving through a specific area or point during a period of time.

- Valve It's a device that controls, regulates or directs the flow of a fluid by opening, closing or partially obstructing passageways.

- Water consumption It's the quantity of water used by people, agriculture, and industries for daily activities like cooking, drinking, farming, and manufacturing

- Environmental crisis An actual serious problem affecting nature, caused by the human impact that harms ecosystems and threatens life on Earth resulting in climate change and species extinction.

- User awareness Knowledge and understanding by people about how their actions affect resources such as water, with the aim of promoting their responsible and sustainable use.

- Safe water It is the kind of water which is drinkable or suitable for personal hygiene, without representing any risk to health.

- Greywaters This is wastewater from domestic or office uses that does not contain fecal contamination, such as that coming from showers, toilets, washing machines or sinks.

- Water reuse The process of treating and repurposing wastewater, stormwater, or graywater for beneficial uses

- Water recycle The process of treating wastewater to remove impurities so that it can be reused for the same or different purposes, reducing water waste and promoting sustainable resource management. While water reuse generally refers to using treated water for various applications, water recycling emphasizes the process of purification and returning water to a system for continued use.

2.3 Products

In this section you can find a research on some of the products that are already on the market which address water waste in households:

Shower Timer (See figure 1)

The user sets a shower time and how many showers a day should be available. When the user presses the start button, the shower timer starts counting back; when the time is off, the shower water is also cut off until the next available shower period. It is designed for domestic and commercial use in Australia. A regular shower uses between 8L and 15 L per minute, so considering a 13 min shower at 12 L/min, it would be using 156 L. If the shower length was reduced to 6 min, it would save 84 L.

When it’s on it consumes less than 10 W, and when it’s not in use it consumes less than 2 W. So this solution helps to avoid unnecessary long showers, compromising the user’s comfort, but improving the customer's finances.

Flow and temperature meter connector (See figure 2)

Device that measures the temperature and water flow, so users are more conscious about the energy and water usage. It is a connector to place in the shower head cord with a display that shows the temperature and the water consumption in real time. It has an LED frame around the display that changes colors from green to red depending on the water consumption, so the user knows when they are wasting too much water.

Furthermore, it works without any battery thanks to a dynamo, so it doesn’t increase energy consumption.

Shower regulator (See figure 3)

A flow regulator is a device that is installed between the shower head and the hose in order to control and limit the flow of water. Its main purpose is to reduce water consumption without compromising a comfortable and enjoyable shower. This device incorporates a small opening or valve mechanism that restricts the water flow. Some models use rubber or plastic diaphragms that adapt to the water pressure to maintain a constant flow rate, while others have fixed orifices that allow up to a certain volume of water per minute.

Flow regulators can be found in different capacities, usually between 14 L/min and 6 L/min.

Faucet aerator (See figure 4)

Faucet aerators are small attachments that screw onto the tip of a faucet, they are a type of water flow regulators. They help control water flow by mixing air with water, creating a smooth, non-splashing stream. Because of their compact design, aerators blend with the faucet, making them hardly noticeable at first glance.

Like shower flow regulators, faucet aerators come in different flow rate options from 14 L/min to 4,5 L/min, allowing customers to choose how much water is restricted.

WOTA box (See figure 5)

WOTA Box is a portable water reuse system that enables water use even with no water supply. More than 98 % of wastewater is reused, delivering safe and reliable water anytime, anywhere.

This product is designed to solve the problem of not being able to bring water in emergency situations or outdoor events. Although it actually needs a power supply source.

WOTA BOX removes more than 99.99 % of viruses and bacteria using four types of filters (one sediment, two activated carbon and one RO membrane), deep ultraviolet rays and chlorine disinfection.

This product relies on AI to monitor and control the quality of the clean water and system and notifies the user when there’s any problem or need for maintenance.

Toilet with integrated sink (See figure 6)

The solution described below is an accessory to put over the toilet tank, although there are other similar solutions, which are a toilet with an integrated sink. The purpose of this accessory is reusing the waste water from washing hands for flushing the toilet. It’s designed to be easy to install.

It also addresses the issue of kids not remembering to wash their hands after using the toilet, and with its touch-free faucet, it breaks the chain of germs. Likewise, it is very suitable for small spaces since the sink room is not needed anymore in the bathroom.

Water Flow Kit (See figure 7)

The kit can be connected to an existing faucet or pipeline, allowing the user to track their water usage accurately. This kit enables real-time monitoring of the water consumption. It can also monitor water temperature and flow.

It has been designed for an easy installation so that the user can do it themselves by just attaching the sensors to the chosen pipeline or faucet and connecting the kit to the home assistant system via Wi-Fi.

The user can also set up alarms or notifications for a certain level of water consumption in order to prevent careless water waste.

Some of the product limitations are the ability to connect only up to two flow sensors, only allowing to track water consumption in two different locations. And also, it’s designed for indoor use, and it’s not recommended for outside use.

2.4 Projects

Water impact awareness campaign

Some associations and agencies have launched campaigns to raise awareness of water misuse, giving users some tips to save water in their daily lives such as EPA(United States Environmental Protection Agency), WaterWiseEU, EPAL (Grupo de Águas de Portugal).

Hydraloop [Hydraloop, 2025].

This project from the Netherlands and Belgium offers products to recycle waste water from the shower, purifying it and bringing it back to the system. It reduces the water use by 25 % - 45 %.

Grey Water Action [Grey Water Action, 2025].

This project, from a collaborative of educators and the California Department of Water Resources, leads people on grey water systems in order to reuse it in irrigation systems.

One Drop Foundation [One Drop, 2025].

It's a nonprofit foundation that is organizing water-saving initiatives worldwide to guarantee safe access to water for different communities.

2.5 Comparative Analysis

Figure 2 shows a comparative analysis of all products and projects that are related to what the team wants to achieve.

| Product | Cost(€) | Way of saving water | Quantity of saved water | Personalization | User awareness | Smartness | Design |

| Shower Timer | 193.94 - 354.16 | Turning off the water after the time set by the user | 84L(calculated for a 6min shower and a regular shower being 13min at 12 L/min) | The users set their own time | It helps the user be aware of how long they take to shower | Timer connected to the water outflow | Simple, not really attractive |

| Flow and temperature meter connector | 20.89 | It only saves water if the user wants to | None | None | It makes the user aware of using to much energy or water | Temperature and pressure sensor displayed in a screen | Attractive, very modern |

| Shower regulator | 9.90 | Limits the water flow in the shower | 26L (calculated for a 13 min shower at 10 L/min, compared to a same time shower but at 12 L/min) | None | The user can be not aware at all | No smart components | Good, small and simple |

| Faucet aerator | 7.36 | Mixes water with air, reducing water flow in faucets | 9 to 6 L/min | None | The user can be not aware at all | No smart components | Good, small and simple |

| WOTA box | Full disaster shelter package around 30.60 | Recycling water | Reuse 98 % of the water | None | The user just has to be aware if the box notifies them of a problem | Sensors and AI to monitor and control water quality | designed for emergencies |

| Water Flow Kit | 54.99 | The user can set alarms for any quantity of water they find excessive, and that way reduce the use | It saves as much water as the user is willing to | The user sets their limits and receive all the data from their household | It makes the user fully aware of their water and energy consumption and gives them tips on how to save money, energy and water | Smart device connected to an APP | - |

2.6 Summary

Based on this study on the state of the art, the team decided to focus on recycling water from the shower.

Inspired by the WOTA box technology, the final product could be a redirection from the shower waste water to the house water system. The problem with this kind of project is purifying the water and the maintenance the system would need. There’s where another solution comes up; the project could be focused on the clean water that goes to waste before actually showering, just because it’s too cold. Inspired by the water flow kit, the solution could track the temperature of the water and only let it run when it’s warm enough. That way there wouldn’t be any need for filters or chemicals, and the not-warm-enough water would go back to the boiler.

Also inspired by the toilet with integrated sink, another solution would be redirecting the cold water or the shower waste water to the toilet tank instead of the boiler, and as a result, saving energy.

3. Project Management

This chapter will address the topic of project management. It will present a comprehensive overview of the practical aspects of project management, including key elements such as stakeholders, costs, procurement, scope, and time. Project management is a crucial part of the project since it ensures the formation of a highly organised team. This, in turn, leads to the successful completion of a project that aligns with the needs of stakeholders, meets the desired scope, and provides team members with a good view of what is going on.

3.1 Scope

The team designed a system using a microcontroller that continuously measures the temperature of the input water from the boiler. If the temperature is below an input (, the water is automatically divert to a storage tank instead of being wasted. This stored water is later used to flush the toilet, giving it a second life and reducing overall water consumption. The following chapter defines the project's boundaries by outlining the overall project scope (Figure 8), detailing the work required to achieve each.

In order to effectively manage the project scope, the work will be further divided into the different deliverables that the team has to hand over in the wiki expressed in this work task breakdown structure:

3.2 Time

The EPS teams have to complete a list of milestones (See figure 3).

| Date | Description |

| 2025/03/01 | Choose and share the team's top 3 preferred project proposals |

| 2025/03/12 | Upload the “black box” System Diagrams & Structural Drafts |

| 2025/03/15 | Define the Project Backlog , Global Sprint Plan, Initial Sprint Plan and Release Gantt Chart of the project |

| 2025/03/19 | Upload the List of Components and Materials (what & quantity) |

| 2025/03/26 | System Schematics & Structural Drawings to the wiki (Deliverables) and do the cardboard scale model of the structure |

| 2025/04/06 | Interim Report and Presentation |

| 2025/04/10 | Interim Presentation, Discussion and Peer, Teacher and Supervisor feedbacks |

| 2025/04/15 | 3D model video |

| 2025/04/29 | Final List of Materials (local providers & price, including VAT and transportation) |

| 2025/05/02 | Refined Interim Report (based on Teacher & Supervisor Feedback) |

| 2025/05/14 | Packaging solution and Report |

| 2025/05/28 | Results of the Functional Tests |

| 2025/06/15 | Final Report, Presentation, Video, Paper, Poster and Manual |

| 2025/06/18 | Final Presentation, Individual Discussion and Assessment |

| 2025/06/25 | Update the wiki, report, paper with all suggested corrections |

| Hand in to the EPS coordinator a printed copy of the poster, brochure and leaflet | |

| 2025/06/26 | Hand in the prototype and user manual to the client |

3.3 Cost

The total cost of those components is 912.42 € and that would just be for one unit of the product. Also, the team is composed of a staff as seen in the table with salary budgeting [Glassdoor, 2025]. Since the project lasts 5 months, the total budget for the staffs salary will be 76000 € (See Table 4). Furthermore, there's a set budget for the prototype of 100 € which is the budget this EPS project should adjust to. (See Figure 9).

| Role | Monthly Salary (estimated) | Total Cost (5 months) |

|---|---|---|

| Project Manager | 3000 € | 15000 € |

| Electrical Engineer | 2500 € | 12500 € |

| Mechanical Engineer | 2500 € | 12500 € |

| Sales Manager | 2800 € | 14000 € |

| Sales Person | 1800 € | 9000 € |

| Design Engineer | 2600 € | 13000 € |

| Total salary budget | 76000 € |

3.4 Quality

The team has documented quality metrics that apply to the project deliverables, associated thresholds and how they should be reviewed (See Figure 5 and 6).

| Metrics | Description | Threshold | Reviewing method |

|---|---|---|---|

| Material durability | Housing should be waterproof and resistant to any minor impacts | Doesn’t let water in through the joints, and its lifespan is a minimum of 10 years | Impermeability testing and stress testing |

| Energy efficiency | Uses as little energy as possible | Max 45W in worst-case scenario | Energy consumption testing |

| Temperature sensor performance | Precision in sensing the water temperature | User input temperature with max ±2ºC deviation | Temperature sensing test |

| Valves and programming performance | Valves open or close pipes entryway as programmed | No errors; when the water is warm enough, the program makes the shower head valve open and close the toilet tank valve | Usage test |

| Maintenance and repairability | Components should be easy to replace or repair | Non-dangerous components should be easy to replace without specialized tools | Maintenance test |

| Eco-efficiency and sustainability | The product must align with sustainable engineering principles explained in Chapter 5 | The product helps to improve the environment, and at its life end, its components can be recycled or reused | Lifecycle assessment |

| Metrics | Description | Threshold | Reviewing method |

|---|---|---|---|

| Clarity | It is easy to understand everything that's explained in the document | No confusing information or writing | All the team members read the documents to make sure it can be understood easily |

| Good spelling | The words can be read without any confusion | No orthographic or grammar mistakes | Run the texts through a spell checker |

| Completeness | The documents contain what the deliverable asked for | All necessary information is included in the documentation | Team members verifying |

| Accuracy | The reader can trust the information written on the documents | There's no fake information source | Ensure that information provided in the documentation is accurate and up-to-date |

3.5 People

People participating in a project can cause a high risk of unpredictability, that is why it is important to organize and delegate tasks among all the parties & team members involved in the project. This particular section outlines the key individuals and groups involved in the project, and describes their roles, responsibilities, and contributions to the project .

The key to successfully delegating tasks is to keep in mind the following aspects of the group members:

- Skills and Expertise: Knowing the skills and capabilities of the team members is fundamental when assigning tasks, so that the outcome can be the best possible.

- Roles and Responsibilities: In order to avoid confusion and overlap, it is important to define the roles and responsibilities of each member and make sure that the tasks align with that.

- Availability and Workload: Equity is a synonym of fairness. When talking about workload, it is important to make sure no team member is overburdened to prevent burnouts.

- Interest and Motivation: Assigning team members tasks they are interested in will improve their engagement and productivity in the project.

- Collaboration and Team Dynamics: Sharing tasks should promote teamwork and collaboration, so in order to get that, it is necessary to know how team members work together.

Azuloop doesn’t have any project manager, resulting in that all team members have the same responsibility among project management, and following the scope. See on the table 7 the roles and responsibilities of the different individuals and groups involved in the project.

| People | Role | Responsibility |

| ISEP | Sponsor | Accept project deliverables. Support Economically |

| Akseli Järvimäki | Team member | Participate in defining change resolutions. Evaluate the need for scope changes and communicate them to the rest of the team and the EPS coordinator as necessary |

| Berta Marcó Giménez | Team member | Participate in defining change resolutions. Evaluate the need for scope changes and communicate them to the rest of the team and the EPS coordinator as necessary |

| Darius-Alexandru Ion | Team member | Participate in defining change resolutions. Evaluate the need for scope changes and communicate them to the rest of the team and the EPS coordinator as necessary |

| Esmée Keijzer | Team member | Participate in defining change resolutions. Evaluate the need for scope changes and communicate them to the rest of the team and the EPS coordinator as necessary |

| Kristoffer Julin | Team member | Participate in defining change resolutions. Evaluate the need for scope changes and communicate them to the rest of the team and the EPS coordinator as necessary |

| Luna Hongenaert | Team member | Participate in defining change resolutions. Evaluate the need for scope changes and communicate them to the rest of the team and the EPS coordinator as necessary |

| Maria Benedita Malheiro | EPS coordinator | Organize and facilitate scheduled control meetings. Facilitate scope change requests. |

| EPS Coaches | Supervisors | Supervise and guide the team through the process |

| Professors | Advisors | Advise the team through their acknowledgement. Provide resources and knowledge |

| Target Group | Costumers | Communicating their needs |

| Suppliers | Supplier | Supply components |

| Retail Stores | Distributors | Sell the product |

3.6 Communications

The team documented how they will manage communications and meetings, which communication channels they use, etc.

Guideline for meetings

Meeting agenda

The Meeting Agenda will be uploaded to the wiki page at least 1 day in advance of the meeting. The Agenda should identify the topics to be discussed or addressed during the meeting.

Meeting minutes

Meeting minutes will be uploaded to the wiki page within the same day as the meeting. Meeting Minutes will include the status of all items on the agenda, along with new agreements discussed in the meeting.

Meeting chair person

The Chair Person is responsible for uploading the Meeting Agenda and leading the meeting. This role will change each meeting, letting all team members lead the meeting, usually according to the expertise of each one of them.

Note taker

The Note Taker will change every meeting, just like the Chair Person. The Note Taker is responsible for documenting everything discussed in the meeting and using those notes to complete and upload the Meeting Minutes.

Time keeper

Usually the time keeper will be a professor. Its responsibility is to help the team adhere to the time limit, letting the Chair Person know when they are approaching the end of their given time.

Communications matrix

In the matrix is stated what types of communication the team used, the objective, medium, frequency, audience and deliverable of those communication types (See figure 8).

| Communication type | Objective | Medium | Frequency | Audience | Deliverable |

| Kickoff meeting | Introducing the team members. Decide on a topic for the project. | Face to face | Once | Team members | None |

| Control meetings | Review status of the project. Report the status of the project including activities, progress and issues. | Face to face | Weekly, every Thursday morning | Team members and project supervisors | Meeting Agenda, Meeting Minutes, Week report |

| Project team meeting | Discuss and develop project issues | Face to face | As needed | Team members | Jira update |

Communication tools and means

- Microsoft Teams: It is the most used tool by the professors and supervisors to upload information and resources.

- Outlook: It is the medium through which the formal communication that needs to be fast is sent.

- WhatsApp: It is the most used mean for fast communication with the team members. The team uses it daily and communicates issues that need to be solved quickly.

- Jira: It is the main tool for project management; the team uploads their progress, completes the sprint reports, and is used for knowing and communicating the tasks and scopes.

Communication approaches

The team documented how they communicate with the stakeholders (See figure 9).

| People | Role | Approach | Frequency |

| Akseli Järvimäki | Team member | F2F | 5x/week |

| Berta Marcó Giménez | Team member | F2F | 5x/week |

| Darius-Alexandru Ion | Team member | F2F | 5x/week |

| Esmée Keijzer | Team member | F2F | 5x/week |

| Kristoffer Julin | Team member | F2F | 5x/week |

| Luna Hongenaert | Team member | F2F | 5x/week |

| Maria Benedita Malheiro | EPS coordinator | Weekly meetings & email | 1x/week |

| Professors | Advisors | Classes or email | 2x/week |

| Suppliers | Supplier | Email & phone | 2x/week |

| Retail Stores | Distributors | Email & phone, also F2F | 2x/week |

3.7 Risk

The risks associated with this project can be divided into three categories: technical risks, installation risks, and safety risks. Each of these has the potential to affect the reliability, usability, and safety of the system. Below we describe each risk type, its potential impact, and suggest ways to mitigate them. (See Figure 10).

Technical risks

-Sensor failure: Could result in incorrect water routing, leading to cold water going to the shower or overflowing the toilet reservoir.

-Microcontroller failure: May cause total system malfunction, stopping valve control and logic execution.

Response:

-Use reliable, tested components.

-Add redundancy or a manual override if possible.

-Perform regular software and hardware testing.

Installation risks

-Compatibility issues: The system might not fit all shower or toilet models.

-Water leaks: Poor installation or connector mismatch could result in leaks.

Response:

-Provide detailed installation guides.

-Use standard fittings and connectors.

-Test prototypes on different fixture types.

Safety risks

-Melting or overheating: If the case or components are made of unsuitable material or poorly ventilated.

-Electrical hazards: Risk of shock if 230V components are exposed or wiring is incorrect.

Response:

-Use flame-retardant, waterproof housing.

-Make sure to let a professional to the installing.

-Separate high and low voltage components properly & keep metallic parts grounded to protect from touch voltages in case of grounding faults.

-Ensure compliance with electrical safety standards (e.g. CE marking, IP classing, LVD ).

Procurement

-Delayed component delivery: may cause timeline delays, and project cancellations. -Quality issues: May cause timeline delays, and project cancellations. -Limited availability: May cause timeline delays and project cancellations. -Cost fluctuations caused by market change: Exceedings of budget.

Response:

-Select reliable suppliers -Keep in mind backup suppliers -Order early -Lock component prices with contracts with suppliers

Communication

-Unclear communication between team and stakeholders: Can lead to wrong decisions being made. -Poor communication between team members: Can lead to project task overlaps as well as missed deadlines -Poor documentation: Can lead to important details being neglected/forgotten

Response:

-Use Jira as a project management tool -Take meeting notes -Set clear deadlines -Hold briefings to make sure everyone is well informed

Risk level definition

1-4 = Low risk

- Minimal impact on project outcomes.

- Issues can be managed easily without disrupting timelines or budgets.

- Usually requires routine monitoring only.

5-9 = Medium risk

- May cause moderate delays or increased costs.

- Could affect some project deliverables or quality.

- Needs planned mitigation and regular review to avoid escalation.

10-15 = High risk

- Likely to cause significant disruption or cost overruns.

- May impact core functionalities or safety.

- Requires immediate mitigation efforts and close management attention.

16-25 = Critical risk

- Threatens overall project success and safety.

- Can cause severe financial loss, legal issues, or safety incidents.

- Demands urgent, comprehensive mitigation and contingency planning.

Possibility & Impact

- The possibility factor of a risk matrix is defined from 1-5, where 1 indicates very unlikely, and 5 very likely.

- The impact factor of a risk matrix is also defined from 1-5, where 1 indicates very low impact, and 5 very high impact.

Risk assessment See the risk assassment the team made below (See figure RiskAssassment).

| Type of risk | Risk | Possibility (1-5) | Impact (1-5) | Risk Score (PxI) | Risk Level | Mitigation Strategy |

|---|---|---|---|---|---|---|

| Technical | Sensor failure: Incorrect water routing | 3 | 4 | 12 | High | Use reliable sensors, use counter-acting valves to have a 'standard position', regular testing |

| Technical | Microcontroller failure | 2 | 5 | 10 | High | Use reliable microcontroller, use of water protected casing |

| Installation | Compatibility issues with fixtures | 3 | 3 | 9 | Medium | Clear documentation, test on multiple models, adaptable fittings |

| Installation | Water leaks from poor installation | 3 | 4 | 12 | High | Quality connectors, detailed guides, installation testing |

| Safety | Melting/Overheating due to poor materials | 2 | 4 | 8 | Medium | Flame-retardant materials, good ventilation |

| Safety | Electrical hazards (shock risk) | 2 | 5 | 10 | High | Professional installation, separate voltages, follow safety standards, use waterproof casing |

| Procurement | Orders not arriving on time | 2 | 5 | 10 | High | Choosing trusted vendors, with good stock |

| Procurement | Components not available in stock | 3 | 5 | 15 | High | Choosing alternative vendors with fast delivery times |

| Communication | Miscommunication | 4 | 4 | 16 | High | Clear roles in the group, as well as briefings to make sure everyone is informed |

3.8 Procurement

The project's procurement plans have been based on a list of external sources of webshops for the components. Due to the wide variety of needed components we decided on purchasing the components from different websites. Since the procurement is an important part, there is also a need to define rules regarding the suppliers, time limits, and the possibility of locking a price contract with the selected suppliers, another important thing to keep in mind is to also have trusted backup suppliers in case the primary suppliers stock runs out.

The valves are going to be acquired from Digikey due to their good high quality selection of products.

The procurement strategy is based on table 11, in which are stated primary suppliers as well as back-up suppliers.

| Component | Digikey | PTRobotics | Farnell | RS Components | Leroy Merlin | Foxschandlery | Factory Made | Fruugo | Time Requirement | Cost (€) | Quantity |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Valve NO | Primary | Backup | 2–5 days | 626.86 | 2 | ||||||

| Valve NC | Primary | Backup | 2–5 days | 184.72 | 2 | ||||||

| Copper pipe | Backup | Primary | 2–5 days | 6.82 | 1 | ||||||

| Microcontroller | Primary | Backup | 2–5 days | 11.75 | 1 | ||||||

| Float switch | Primary | Backup | 2–5 days | 2.28 | 2 | ||||||

| Relay | Backup | Primary | 2–5 days | 3.69 | 3 | ||||||

| Temperature sensor | Backup | Primary | 2–5 days | 5.35 | 1 | ||||||

| Voltage regulator | Backup | Primary | 2–5 days | 7.32 | 1 | ||||||

| T pipe fitting | Primary | Backup | 2–5 days | 1.78 | 1 | ||||||

| Male push-in fitting | Primary | Backup | 2–5 days | 11.67 | 3 | ||||||

| Female push-in fitting | Primary | Backup | 2–5 days | 24.27 | 3 | ||||||

| Bulkhead G3/8 | Primary | Backup | 2–5 days | 27.02 | 2 | ||||||

| Thread adapter | Primary | Backup | 2–5 days | 22.17 | 3 | ||||||

| Case | Primary | 7 days | 31.00 | 1 | |||||||

| Protective corner tape | Backup | Primary | 2–5 days | 17.95 | 1 |

3.9 Stakeholders Management

Stakeholder management refers to the identification, analysis, engagement, and continuous communication with individuals or organizations that can affect or be affected by the project. Effective stakeholder management is essential to ensure that the project runs smoothly, meets expectations, and achieves its goals within the required scope, time, and budget. (See Figure 11).

Key Stakeholders in Our Project:

Team members

-Responsible for designing, prototyping, testing, and reporting.

-Key for innovation, decision-making, and implementation.

-Regular internal meetings to align progress and resolve issues.

Project Supervisor (EPS Coordinator)

-Provides guidance, feedback, and ensures academic requirements are met.

-Acts as a communication link with the institution and faculty.

-Reviews deliverables and gives approval for project milestones.

ISEP / Hosting Institution

-Offers resources such as laboratory space, tools, and technical support.

-Ensures a safe and professional learning environment.

-Provides deadlines, academic structure, and evaluation criteria.

Clients / End Users

-Potential beneficiaries of the solution (e.g. homeowners, building developers, facility managers).

-Their needs influenced the design choices (e.g. water-saving functionality, usability).

-Feedback was considered during the initial design phase.

Technical Advisors / Mentors

-Offer domain-specific expertise (e.g. plumbing, electronics, automation).

-Help troubleshoot technical challenges and validate solutions.

-Occasionally consulted throughout the development process.

Suppliers / Manufacturers

-Provide components (e.g. valves, microcontrollers, relays).

-Delivery time and product quality affect project schedule and functionality.

Engagement Strategy:

-Weekly team meetings and progress reviews.

-Midterm and final presentations for feedback from ISEP faculty and peers.

-Email and face-to-face communication with mentors and supervisors.

-Documentation and progress updates via shared platforms (e.g. Google Drive, Teams).

-Prototypes and testing results shared for validation before final implementation.

Risk Mitigation Related to Stakeholders:

-Regular communication to prevent misunderstandings or delays.

-Clear role distribution and responsibilities among team members.

-Early involvement of advisors to validate design feasibility.

-Continuous feedback loops to ensure alignment with stakeholder expectations.

3.10 Project Plan

The team has a global sprint plan (See figure 12).

| Sprint | Start | Finish | Working days |

|---|---|---|---|

| 1 | 27 february | 5 march | 3 days of availability |

| 2 | 6 march | 12 march | 5 days of availability |

| 3 | 13 march | 19 march | 5 days of availability |

| 4 | 20 march | 26 march | 5 days of availability |

| 5 | 27 march | 2 april | 5 days of availability |

| 6 | 3 april | 9 april | 5 days of availability |

| 7 | 10 april | 16 april | 5 days of availability |

| 8 | 17 april | 23 april | 0 days of availability |

| 9 | 24 april | 30 april | 3 days of availability |

| 10 | 1 may | 7 may | 2 days of availability |

| 11 | 8 may | 14 may | 3 days of availability |

| 12 | 15 may | 21 may | 5 days of availability |

| 13 | 22 may | 28 may | 5 days of availability |

| 14 | 29 may | 4 june | 5 days of availability |

| 15 | 5 june | 11 june | 4 days of availability |

| 16 | 12 june | 18 june | 5 days of availability |

The team got a project backlog in the briefing, which they should finish by the end of the semester (See figure 13).

| PBI | Title | Status |

|---|---|---|

| A | Define project | Done |

| B | System diagrams and structural plans | Done |

| C | Project Backlog | Done |

| D | State of the Art | Done |

| E | Gantt chart | In progress |

| F | System Diagrams and Drafts | Done |

| G | Global sprint plan | In progress |

| H | List of Components and Materials | Done |

| I | Schematics and Structural Drawings | Done |

| J | Design development | Done |

| K | Interim deliverables | Done |

| L | 3D model and video | Done |

| M | Interim Report and Presentation | Done |

| N | Functional Testing | Done |

| O | Packaging solution | To do |

| P | Poster | To do |

| Q | Folder and manual | To do |

| R | Brochure and Leaflet | To do |

| S | Prototype | Done |

| T | Video | To do |

| V | Final report | To do |

| W | Upload Final Deliverables | To do |

| X | Final presentation | To do |

| Y | Final Review and Submission | To do |

| Sprint | Task | Duration (d) | Responsible | Involved |

|---|---|---|---|---|

| 1 | A | 2 | All | All |

| 2 | B,C,D | 3 | All | All |

| 3 | E,F,G,H | 5 | All | All |

| 4 | I,J | 3 | All | All |

| 5 | B,F,O | 5 | All | All |

| 6 | L,K | 2 | All | All |

| 7 | H,K,L | 4 | All | All |

| 8 | O,P,R,S | 4 | All | All |

| 9 | B,I,S,H | 5 | All | All |

| 10 | J,S | 3 | All | All |

| 11 | J,N,S,Q | 4 | All | All |

| 12 | J,L,S,P | 4 | All | All |

| 13 | S,L,M | 5 | All | All |

| 14 | S,L,V | 3 | All | All |

| 15 | N,S,V,Q | 3 | All | All |

| 16 | N,S,T,X | 4 | All | All |

| Sprint | PBI | Responsible | Involved | Status |

|---|---|---|---|---|

| 1 | A | All | All | Done |

| 2 | B,C,D | All | All | Done |

| 3 | E,F,G,H | All | All | Done |

| 4 | I,J | All | All | Done |

| 5 | B,F,O | All | All | Done |

| 6 | L,K | All | All | Done |

| 7 | H,K,L | All | All | Done |

| 8 | O,P,R,S | All | All | Done |

| 9 | B,I,S,H | All | All | Done |

| 10 | J,S | All | All | Done |

| 11 | J,N,S,Q | All | All | Done |

| 12 | J,L,S,P | All | All | Done |

| 13 | S,L,M | All | All | Done |

| 14 | S,L,V | All | All | Done |

| 15 | N,S,V,Q | All | All | Done |

| 16 | N,S,T,X | All | All | In progress |

3.11 Sprint Outcomes

3.11.1 Sprint 1 – Team Formation and Problem Exploration

During the first sprint, the team focused on team building and brainstorming. They explored various everyday problems and discussed ideas on how technology could help improve daily life. One recurring theme was the waste of clean cold water while waiting for hot water in the shower. This led to ideas about how water consumption could be reduced in households.

Sprint 1 – Burnup chart (See figure 13)

Sprint end status: The project was succesfully defined, and all of the tasks were completed successfully. Planned velocity for this sprint was 7 tasks, and achieved velocity was 7 tasks.

3.11.2 Sprint 2 – Concept Development

In the second sprint, the team deepened their understanding of the water waste issue. The initial idea was to capture the cold water that runs before hot water arrives in the shower, and somehow reuse it. One early idea was to return the cold water to the boiler. The team began to research water flow, temperature sensors, and basic plumbing systems to assess feasibility.

Sprint 2 – Burnup chart (See figure 14)

Sprint end status: The making of initial system diagrams, structural plans were started, and the project backlog as well as the state-of-the-art analysis was completed. Planned velocity for this sprint was 15 tasks, and achieved velocity was 15 tasks.

3.11.3 Sprint 3 – Solution Decision and Naming

During the third sprint, the team made a key decision: the cold water would be routed to the toilet flush tank instead of being wasted. This concept combined simplicity and functionality. The project got the name “AzuLoop”. The focus then shifted to identifying necessary components, such as valves, sensors, and control logic. The team also started drafting basic system diagrams.

Sprint 3 – Burnup chart (See figure 15)

Sprint end status: The gant chart, global sprint plans were all completed. Planned velocity for this sprint was 13 tasks, and achieved velocity was 13 tasks.

3.11.4 Sprint 4 – Design Development and Component Collection

In the fourth sprint, the team refined the system design and created electrical diagrams. They confirmed how the logistics will work and finalised the list of components.

Sprint 4 – Burnup chart (See figure 16)

Sprint end status: Schematics and structural drawings were completed for the time being, the team also started thinking about the designing. Planned velocity for this sprint was 10 tasks, and achieved velocity was 10 tasks.

3.11.5 Sprint 5 – Redesigning and rethinking

In the fifth sprint the team changed the product. They decided to redesign and create a product to redirect the cold water from the shower to the toilet tank. Also the cardboard model was done, which helped to get a visual image of the actual product. The team updated the components list for the prototype.

Sprint 5 – Burnup chart (See figure 17)

Sprint end status: New revisison for the system diagrams and schematics were completed after receiving feedback about the current version. Planned velocity for this sprint was 12 tasks, and achieved velocity was 12 tasks.

3.11.6 Sprint 6 - Refining the interim report

In the sixth sprint, the team made the 3D model for the product, and started refining the interim report as asked. They also calculated the product cost and the expected cost of operation.

Sprint 6 - Burnup chart (See figure 18)

Sprint end status: The initial interim deliverable tasks were started. Planned velocity for this sprint was 15 tasks, and achieved velocity was 15 tasks.

3.11.7 Sprint 7 - 3D modeling and component joining & electrical connection

During the seventh sprint finished the final component list for the product, finalised the interim report and improved the cost calculation.

Sprint 7 - Burnup chart (See figure 19)

Sprint end status: The research of components and materials for the prototype were started, interim deliverables were prepared, and the 3D model and video were completed. Planned velocity for this sprint was 11 tasks, and achieved velocity was 11 tasks.

3.11.8 Sprint 8 - Graphic & Packaging design

In the eighth sprint the team uploaded the leaflet and the poster, the first paper abstract version and the proposed packaging solution.

Sprint 8 - Burnup chart (See figure 20)

Sprint end status: The packaging solution, poster, brochure, and leaflet were developed. Planned velocity for this sprint was 11 tasks, and achieved velocity was 11 tasks.

3.11.9 Sprint 9 - Project planning for prototype

During the ninth sprint, the team successfully managed to plan the prototype's hardware and software configuration and also managed to order the parts for it before Easter break.

Sprint 9 - Burnup chart (See figure 21)

Sprint end status: System diagrams and schematics and were controlled for the prototype, and the list of components and materials were all refined and completed again.

3.11.10 Sprint 10 - Prototype & scientific paper

During the tenth sprint, the team started assembling and soldering the components they had and they started coding the prototype. Because of the missing components they were a little behind with the prototype assembling. The first and second chapter of the scientific report were also submitted, for sprint 10 there is no burnup chart available.

Sprint end status: Design development continued after new feedback, and we did some more research and building of the prototype.

3.11.11 Sprint 11 - Prototype & scientific paper

During the eleventh sprint, the team assembled the components of the prototype (pipes and electrical components), but they had some problems with the coding and electronic components. For sprint 11 there is no burnup chart available.

Sprint end status: The team managed to assemble the hardware for the protoype, but ran into setbacks with the coding of the microcontroller.

Sprint end status: Functional testing of the electrical components and pressurization test of the system was done, and the manual was made.

3.11.12 Sprint 12 - Prototype & scientific paper

During the twelfth sprint the team started doing technical documenting work regarding the prototype, the team did not yet receive a functioning powersupply, and therefore we could not achieve much further progress. For sprint 12 there is no burnup chart available.

Sprint end status: The team managed to successfully complete the technical documenting work, but ran into setbacks regarding the malfunctioning powersupply.

3.11.13 Sprint 13 - Prototype & scientific paper

During the thirteenth sprint the team continued the report writing, as well as doing correction work for the report, the microcontroller also got damaged presumably by overvoltage or overcurrent, causing further delays with the functional testing part.

For sprint 13 there is no burnup chart available.

Sprint end status: The team managed to do significant progress with the coding as well as report corrections, but ran into a setback with a malfunctioning microcontroller, and therefore could not proceed with the prototype development.

3.11.14 Sprint 14 - Prototype & scientific paper

During the fourteenth sprint, the team received a functioning power supply and we managed to complete the assembly of the prototype, but they had a problem with the thermostat for the water distribution controlling, and therefore we couldn't complete all of the functional tests. For sprint 14 there is no burnup chart available.

Sprint end status: The team managed to get a new microcontroller and do the programming, but we ran into a setback with the thermostat, otherwise everything was going as planned.

3.11.15 Sprint 15 - Assembly of prototype and functional testing

During the fifteenth sprint, the team successfully managed to fix the microcontroller and the temperature measurement, after which the prototypes functional tests were succesfully completed, the team also managed to do significant progress with the scientific report writing.

For sprint 15 there is no burnup chart available.

Sprint end status: The team managed to successfully get the prototype working, and successfully completed the functional tests with success, also the scientific report was completed.

3.11.16 Sprint 16 - Report writing and completion of final deliverables

For sprint 16 there is no burnup chart available.

Sprint Evaluations

Sprint 1:

Positive: Good communication and open idea exchange within the team.

Negative: It took time to agree on which problem to focus on.

What to improve on: Early team alignment is essential for smooth progress later.

Start doing: Align early on the main problem to solve.

Stop doing: Waiting too long to reach consensus.

Keep doing: Encouraging open communication and idea sharing.

Sprint 2:

Positive: Solid concept development and active engagement in discussions.

Negative: We had some mixed opinions on what we should work on.

What to improve on: Let everyone know your opinions.

Start doing: Clearly express and explain individual opinions.

Stop doing: Avoiding disagreement—differences can lead to better solutions.

Keep doing: Actively participating in team discussions.

Sprint 3:

Positive: A clear technical direction was established, and the project got its name, AzuLoop.

Negative: As a team everyone agreed that some are working more than others and the work should be more balanced.

What to improve on: Work better as a team. Communication should be a lot better within the whole group.

Start doing: Assign tasks more fairly and communicate expectations.

Stop doing: Letting workload fall unevenly across members.

Keep doing: Defining direction and making big decisions as a team.

Sprint 4:

Positive: We successfully gathered the necessary parts and had better communication.

Negative: Workload was still unbalanced even though having better communication.

What to improve on: More documenting, more communication and teamwork. Balance the workload.

Start doing: Document work and decisions more thoroughly.

Stop doing: Assuming others know who’s doing what.

Keep doing: Working on improving communication.

Sprint 5:

Positive: We successfully managed to create the 3d-model.

Negative: Workload was unbalanced.

What to improve on: More open communication, more briefing.

Start doing: Hold regular briefings to keep everyone updated.

Stop doing: Letting communication drop between work sessions.

Keep doing: Making steady technical progress.

Sprint 6:

Positive: We successfully managed to plan and order parts for the prototype.

Negative: Workload was unbalanced.

What to improve on: More direct communication, as well as more briefing, in order to prevent misunderstandings.

Start doing: Use more direct communication and clarify roles.

Stop doing: Relying on assumptions instead of briefings.

Keep doing: Making clear progress on the prototype.

Sprint 7:

Positive: We successfully managed to finish all the tasks within the deadlines.

Negative: We had to correct several times a task that could have been correct the first time.

What to improve on: We should improve teamwork and communication.

Start doing: Double-check work and give early feedback.

Stop doing: Rushing tasks without review.

Keep doing: Meeting deadlines consistently.

Sprint 8:

Positive: We successfully created a packaging solution and poster for the product.

Negative: Workload was unbalanced again.

What to improve on: Try to help when other teammates have a big workload.

Start doing: Offer help to overloaded teammates.

Stop doing: Working isolated from the team.

Keep doing: Delivering high-quality outputs on time.

Sprint 9:

Positive: We made the deadline for ordering the components for the prototype.

Negative: Didn’t get far with the wiki page.

What to improve on: Keep working on the report even when the deadline isn’t close.

Start doing: Allocate time to documentation early.

Stop doing: Postponing wiki/report work until the last minute.

Keep doing: Meeting operational deadlines.

Sprint 10:

Positive: We started working and planning the prototype and managed to work on the scientific paper.

Negative: We didn’t get all the components needed for the prototype so we didn’t get far with it.

What to improve on: Planning next steps ahead.

Start doing: Plan further ahead to avoid delays.

Stop doing: Relying on last-minute solutions for essential parts.

Keep doing: Advancing both practical and theoretical aspects.

Sprint 11:

Positive: We came far with the prototype and finished the tasks the teachers asked us to do.

Negative: Not all the team members were here.

What to improve on: Work on the project even when we are at home or on vacation.

Start doing: Stay engaged even when remote or on vacation.

Stop doing: Letting physical absence mean disengagement.

Keep doing: Completing assigned tasks and building the prototype.

Sprint 12:

Positive: We got some documentation work done. Negative: Not all team members were here, not all of our components were working. What to improve on: Work on the project even when we are at home or on vacation. Start doing: Stay engaged even when remote or on vacation, start backup -planning. Stop doing: Letting physical absence mean disengagement. Keep doing: Completing assigned tasks effectively and always take notes.

Sprint 13:

Positive: We got a lot of documentation work done. Negative: Microcontroller failed, causing further delays. What to improve on: More open delegation of tasks within the group. Start doing: Plan further ahead to avoid delays. Stop doing: Relying on last minute-solutions for essential parts. Keep doing: Documentation work.

Sprint 14:

Positive: We successfully managed to assemble the rest of the hardware for the prototype, and do pressurization and electrical tests. Negative: Workload was unbalanced, malfunctioning sensor. What to improve on: More open delegation of tasks within the group. Start doing: Start doing documentation work if there is nothing else to do. Stop doing: Let work tasks pile up. Keep doing: Work with the prototype.

Sprint 15:

Positive: We successfully finished the prototype and got the functional tests completed with success, also we got a lot of piled up documentation work done. Negative: We let a lot of documentation work pile up, Not all team members were attending. What to improve on: Keep on doing documentation work if there's nothing else to do. Start doing: Taking notes in order to remember the sprint progress details, work on the project even when we are at home or on vacation. Stop doing: Let background work tasks pile up instead of progressing forward little by little. Keep doing: Working with documentation, Keep open team discussions.

Sprint 16:

Positive: Negative: What to improve on: Start doing: Stop doing: Keep doing:

3.12 Summary

This chapter explains how the team manages their project from the start. The goal was to develop a simple and efficient solution to reduce cold water waste in households. To do this, they applied basic project management tools to organize the work, divide responsibilities according to group members skills, and track the progress.

The team started by clearly defining the scope of the project and the resources available. An estimation of the time needed was made, considering the costs of components, and making sure the right people were assigned to different tasks. Each team member contributed to the work based on their own strengths and background.

Risk management was also an important part of the process. The team identified possible issues early on such as technical failures, installation problems, or safety concerns. This helped for better preparation and avoiding surprises during development.

The team also paid attention to stakeholders, including users, supervisors, and suppliers. Understanding their roles and expectations helped to focus on what matters most and make better decisions during the project.

As the work progressed, the team created technical plans, adjusted our design according to needs and feedback, and gathered the necessary parts. Communication within the team is super important, it makes the work smoother and more efficient.

In the end, good planning, teamwork, and clear goals helped to stay on track and keep the scope focused.

In the next chapter, the team focuses on the marketing strategy of AzuLoop.

Ultimately through applying the agile project management principles and distributing the work between the team members the team finally managed to successfully make the prototype work during sprint number 9.

4. Marketing Plan

4.1 Introduction

How will AzuLoop introduce and grow as an innovative product in the market? This chapter will explain the strategies and tactics.

The purpose of this plan is to provide a clear overview of AzuLoop’s marketing approach, taking into account the current market environment and the project’s objectives. It includes an analysis of the market, an evaluation of AzuLoop’s strengths and weaknesses, opportunities and threats, the chosen strategy with segmentation, targeting, and positioning, as well as the marketing mix, branding, marketing programs, and control mechanisms.

4.2 Business Idea Formulation

The core of the AzuLoop project is addressing water waste caused by people letting cold water run down the drain while waiting for warm water during a shower. The business idea presents a solution in the form of a device that is installed between the water mixer and the showerhead. This device measures the water temperature and stops the flow to the showerhead until the desired temperature is reached. This idea aligns with the marketing concept, which focuses on identifying and fulfilling customer needs as effectively as possible. Instead of wasting the cold water, it is redirected to an additional tank above the toilet reservoir where it will be used to flush the toilet. This means that water only comes out of the showerhead when the desired temperature is reached and no cold water is being wasted through the drain.

4.3 Business Model

The Business Model Canvas (BMC). See Figure 22. Is a strategic tool used to visualize and analyze how a business creates, delivers, and captures value. It provides a structured approach to developing and refining a business model by breaking it down into nine key building blocks:

Value Creation:

- Value Proposition: The main value the business offers to customers.

- Customers: The different groups of people the business serves.

- Channels: The ways the product or service reaches customers.

- Customer Relationships: How the business interacts with and retains customers.

Operations:

- Key Activities: The essential tasks required to run the business.

- Key Resources: The assets needed to operate successfully.

- Key Partners: External organizations that support the business.

Finances:

- Revenue Streams: The ways the business earns money.

- Cost Structure: The main expenses required to operate.

By using the BMC, businesses can identify strengths, address weaknesses, and make informed decisions to improve efficiency and growth.

4.4 Market Analysis

Macro Environment (PESTEL Analysis)

- Political: Many governments are introducing regulations to promote water conservation and sustainability. Some provide financial incentives or tax benefits for installing water-saving products, which could make AzuLoop more attractive to buyers. For instance, in the United States, the IRS offers tax credits for certain energy-efficient home improvements, including water-saving technologies. From 2023 through 2032, homeowners can claim a tax credit of up to 30 % of qualified expenses, with a maximum annual credit of 1 200 USD for energy-efficient property and certain home improvements [IRS, 2025]. EPA’s WaterSense program funds projects that install low-flow showerheads and faucets [Ever Flow Bidets, 2025].

- Economic: Rising water costs encourage consumers to look for long-term savings. AzuLoop offers a cost-effective solution by reducing water waste, making it a valuable investment for homeowners and businesses [Joe Eaton, 2023].

- Social: Awareness of environmental issues is increasing, and more consumers are prioritizing sustainability in their purchasing decisions. Younger generations, in particular, are willing to invest in eco-friendly home solutions [Xebina Hasnee, 2025].

- Technological: Advances in smart home technology and water recycling systems provide opportunities for AzuLoop to integrate with existing innovations, improving product appeal and functionality [Rusé, 2025].

- Environmental: Climate change and water shortages are pushing governments and individuals to adopt water-saving solutions, making AzuLoop a relevant and timely product [Sanjana Gajbhiye, 2025].

- Legal: Regulations requiring water-efficient systems in homes and businesses are becoming more common. Future legal requirements may further increase demand for products like AzuLoop. For example: In Australia, the Water Efficiency Labelling and Standards (WELS) scheme regulates products such as taps, toilets, and dishwashers, requiring them to meet specific water efficiency standards. This program saves significant amounts of water annually and reduces utility costs for households [Autralian Government, 2025].

Customer Segments & Marketing Personas

AzuLoop targets individuals and businesses looking to reduce water consumption and promote sustainability.

Customer Segments

- Eco-Conscious Homeowners: Individuals who prioritize sustainability and want to reduce their environmental impact while saving on water bills.

- Landlords & Property Managers: Owners of rental properties who want to increase the value of their property and attract environmentally conscious tenants.

Marketing Personas

Emma, the eco-conscious homeowner

Emma is 32 years old and has been passionate about sustainability since a very young age. She has always followed sustainability influencers on social media platforms, she reads reviews and shares her experience online. Ever since she got a steady income and bought her own house, she was constantly seeking for eco-friendly solutions in her home. She is even willing to invest in products or systems that promote sustainable behaviour, as long as they are functional and aesthetically pleasing. Although she cares a lot about the environment, she also has to combine her vibrant social life with a big workload at her job, which means that eco-friendly alternatives in her household cannot take up any more time or change her daily routine too much.

David, the smart investor

David owns a few apartments in Bonfim, an upcomming and trendy neighbourhood for young families in Porto. He is interested in sustainability, but mainly focusses on easy to install and low maintenance solutions that reduce water and energy costs over time. He is willing to invest in these kind of solutions if he could increase the value of his property and attract conscious tenants who are looking for sustainable living spaces.

Stakeholders & Retail Channels

AzuLoop will be sold through direct and retail partnerships while avoiding large online marketplaces to maintain brand control.

- AzuLoop’s Own Website: Direct sales through the official website, ensuring customer support and engagement.

- Retail Stores: In contract with home improvement and sustainability-focused stores which allows customers to view the product physically before they make the purchase.

- Retail Store Websites: Some of these partnered stores could offer AzuLoop on their own websites, this raises awareness about the brand for people who don't know AzuLoop yet.

Geographic Market

AzuLoop will target regions where costumers are more likely to invest in water-saving solutions.

- Western Countries: Europe, North America, and Australia, where plumbing standards support AzuLoop’s technology and sustainability awareness is high.

- China & Other Emerging Markets: Countries with a strong base of young, environmentally conscious consumers who are open to adopting innovative green technologies [M. et al. Masukujjaman A. Al Mamun Y. Hong, 2024].

- Water-Scarce Regions: Areas experiencing frequent droughts or water shortages, where water-saving solutions are in high demand.

The competitive analysis has already been discussed in the State of the Art chapter and will be further elaborated on in the “Positioning” chapter.

4.5 SWOT Analysis

The SWOT analysis of AzuLoop identifies its strengths, weaknesses, opportunities, and threats (See figure 23).

4.6 Strategy

AzuLoop's strategy is based on the STP method (Segmentation, Targeting, Positioning).

4.6.1 Strategic Objectives

AzuLoop's strategic objectives fall into three main categories:

Economic Objectives:

- Develop an efficient and sustainable product.

- Offer the best possible product at a reasonable price, based on production costs.

- Make a positive environmental impact by reducing water waste.

Customer-Oriented Objectives:

- Raise awareness about water waste and the importance of sustainability.